Decoding the Language of Value Stream Maps: A Comprehensive Guide to Symbols and Their Significance

Related Articles: Decoding the Language of Value Stream Maps: A Comprehensive Guide to Symbols and Their Significance

Introduction

With great pleasure, we will explore the intriguing topic related to Decoding the Language of Value Stream Maps: A Comprehensive Guide to Symbols and Their Significance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Decoding the Language of Value Stream Maps: A Comprehensive Guide to Symbols and Their Significance

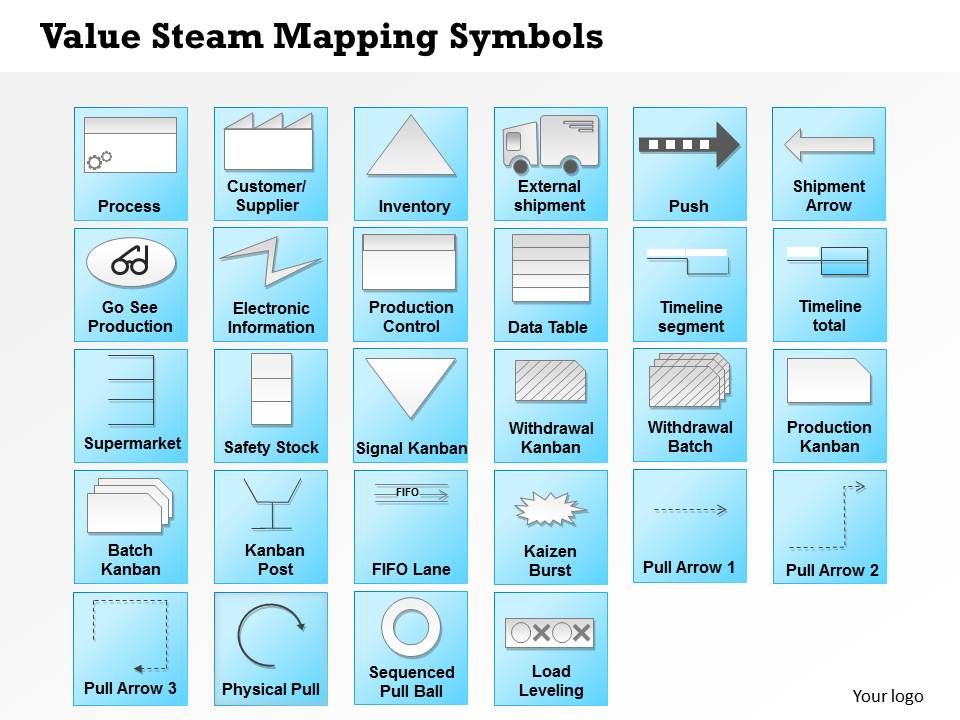

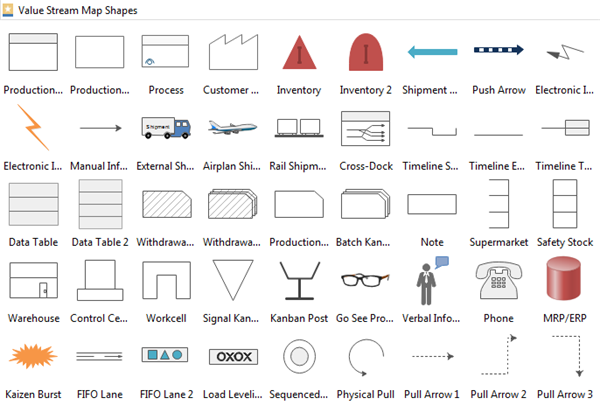

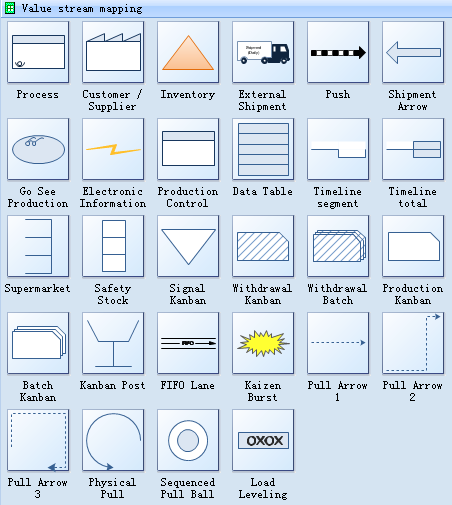

Value stream mapping, a powerful tool for visualizing and analyzing the flow of value in a process, utilizes a standardized set of symbols to represent various activities and elements. Understanding these symbols is crucial for effectively interpreting and utilizing value stream maps. This comprehensive guide delves into the meaning and significance of each symbol, shedding light on their application and contribution to process improvement.

The Building Blocks of Value Stream Maps: A Symbol Glossary

1. Process Boxes:

- Function: Represents a specific process or activity within the value stream.

- Appearance: Rectangular box with the process name clearly labeled inside.

- Example: "Order Entry," "Production," "Shipping."

2. Data Boxes:

- Function: Illustrates data points or information that influence the process.

- Appearance: Diamond shape with the relevant data label inside.

- Example: "Customer Order," "Inventory Level," "Lead Time."

3. Delays:

- Function: Depicts waiting time or delays within the process.

- Appearance: Triangle with the duration or cause of delay clearly labeled.

- Example: "Waiting for Approval," "Inventory Buffer," "Transportation Delay."

4. Inventory:

- Function: Represents the storage of materials or work-in-progress within the process.

- Appearance: Triangle with an inverted apex, labeled with the type of inventory.

- Example: "Raw Materials," "Work-in-Progress," "Finished Goods."

5. Transportation:

- Function: Shows the movement of materials or products between processes.

- Appearance: Arrow connecting two process boxes, labeled with the mode of transportation.

- Example: "Truck," "Conveyor Belt," "Hand Delivery."

6. Operation:

- Function: Highlights a value-adding activity, directly contributing to the product or service.

- Appearance: Rounded rectangle with the operation name labeled inside.

- Example: "Assembly," "Machining," "Testing."

7. Inspection:

- Function: Represents a quality check or inspection point within the process.

- Appearance: Circle with the inspection criteria or standard labeled inside.

- Example: "Visual Inspection," "Functional Test," "Dimensional Check."

8. Customer:

- Function: Marks the end of the value stream, representing the recipient of the product or service.

- Appearance: Rectangle with a person icon inside, labeled "Customer."

9. Supplier:

- Function: Indicates the source of raw materials, components, or services.

- Appearance: Rectangle with a supplier icon inside, labeled with the supplier’s name.

10. Pull:

- Function: Demonstrates the use of a pull system, where production is triggered by demand.

- Appearance: Arrow pointing backwards, indicating the direction of pull.

11. Push:

- Function: Shows the use of a push system, where production is based on a predetermined schedule.

- Appearance: Arrow pointing forwards, indicating the direction of push.

12. Value Stream Boundaries:

- Function: Defines the scope of the value stream, separating it from other processes.

- Appearance: Dashed line surrounding the relevant processes within the map.

Understanding the Power of Symbols: Unveiling Process Insights

These symbols, when combined, form a visual language that unveils the intricacies of a value stream. By analyzing the flow of materials, information, and work, value stream maps highlight areas for improvement:

- Identifying Waste: Symbols like delays, inventory, and unnecessary transportation reveal wasteful activities that add no value to the customer.

- Optimizing Process Flow: Analyzing the sequence of operations, inspections, and transportation helps identify bottlenecks and streamline the process.

- Highlighting Value-Adding Activities: Distinguishing between value-adding and non-value-adding activities allows for focusing resources on essential tasks.

- Promoting Collaboration: Visualizing the entire value stream fosters a shared understanding of the process, encouraging collaboration and communication between teams.

FAQs: Demystifying the Value Stream Map Symbols

Q: What are the key differences between process boxes and operation boxes?

A: Process boxes represent any activity within the value stream, while operation boxes specifically denote value-adding activities directly contributing to the product or service.

Q: Why is it important to include delays in the value stream map?

A: Delays represent wasted time and resources. Identifying and minimizing delays is crucial for improving efficiency and reducing costs.

Q: How does the customer symbol contribute to the overall value stream map?

A: The customer symbol marks the end of the value stream, highlighting the ultimate recipient of the product or service and reinforcing the focus on customer value.

Q: What are the benefits of using a pull system over a push system?

A: Pull systems typically lead to reduced inventory, shorter lead times, and greater responsiveness to customer demand.

Tips for Effective Value Stream Mapping

- Focus on the Customer: Ensure the value stream map clearly depicts the flow of value from the supplier to the customer.

- Use Consistent Symbols: Employ the standard symbols consistently throughout the map for clarity and ease of interpretation.

- Provide Clear Labels: Label each symbol with relevant information, such as process names, data points, and durations.

- Involve Stakeholders: Encourage participation from all stakeholders involved in the process to ensure accurate representation and shared understanding.

- Regularly Review and Update: Regularly review the value stream map and update it as processes evolve to maintain its relevance.

Conclusion: Empowering Process Improvement Through Visual Communication

Value stream map symbols act as a visual language, enabling a clear and concise representation of a process. By understanding these symbols and their significance, organizations can gain valuable insights into their value streams, identify areas for improvement, and drive meaningful change. The ability to visualize and analyze processes using these symbols empowers teams to optimize efficiency, reduce waste, and ultimately deliver enhanced value to customers.

![]()

Closure

Thus, we hope this article has provided valuable insights into Decoding the Language of Value Stream Maps: A Comprehensive Guide to Symbols and Their Significance. We hope you find this article informative and beneficial. See you in our next article!